目录

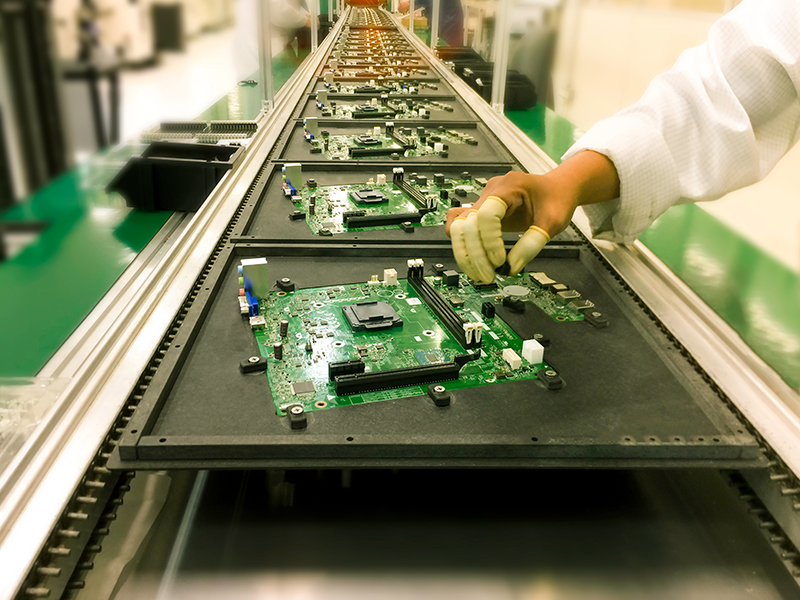

Scalability, accuracy, and efficiency are essential to remaining competitive in today’s fast-paced electronics sector. Electronics Manufacturing Services Printed Circuit Board Assembly, or EMS PCBA, is essential in this situation. By providing comprehensive solutions for PCB design, manufacturing, and assembly, EMS suppliers assist enterprises in streamlining the production of electronic products.

In this article, we will discuss EMS PCBA, why it is important for businesses, and how it may increase production capacity.

EMS PCBA: What is it?

Electronics Manufacturing Services firms that focus on printed circuit board assembly (PCBA) offer a service known as EMS PCBA. To produce a working electronic gadget, electronic components must be soldered onto a PCB. EMS suppliers handle everything from design, prototyping, and testing to mass production and quality control.

A simplified and highly advantageous option for companies aiming to expand their electronics manufacturing or minimize internal costs is collaborating with an EMS supplier for printed circuit boards.

Benefits of Partnering with EMS PCBA Providers

- Economy of Cost

Cost-effectiveness is among the main benefits of outsourcing to EMS PCBA suppliers. By utilizing automated procedures, bulk component sourcing, and EMS provider expertise, companies can lower production costs without compromising quality standards. - Equilibrium

Because EMS suppliers can handle both small—and large-scale productions, firms can expand operations without having to invest in new infrastructure or resources. Thanks to this flexibility, scaling up production when demand rises is simpler. - Quicker Turnaround Time

Through collaboration with an EMS PCBA supplier, companies can shorten the time needed to develop new products. EMS suppliers optimize every stage, from high-volume production to rapid prototyping, to guarantee faster turnaround times and help you get your goods to market sooner. - Concentrate on Fundamental Skills

By outsourcing PCB assembly to EMS partners, businesses can concentrate on their key competencies, such as product design, research and development, and marketing, without being distracted by the intricacies of manufacturing. - Obtaining Advanced Technology

EMS companies consistently invest in automated machinery and state-of-the-art technology to guarantee accurate and superior PCBA services. By collaborating with an EMS provider, you can obtain the newest advancements without making costly machinery purchases for yourself.

How To Choose the Right EMS PCBA Partner

When selecting an EMS PCBA partner, it’s crucial to consider variables like:

- Experience and Expertise: Seek out a supplier who has a track record of success in the particular sector you work in.

- Capacity: Whether you want to produce a small prototype batch or a large-scale product, ensure the supplier has the tools and capacity to satisfy your demands.

- Quality requirements: To guarantee excellent results, confirm that the EMS provider complies with industry certifications like ISO 9001 and IPC requirements.

- Customer Service: Excellent customer service and communication are essential throughout the production process to handle any problems or modifications.

Conclusion

In today’s electronics manufacturing environment, EMS PCBA services are vital. By collaborating with the ideal EMS supplier, businesses can access cutting-edge technology, cost savings, and scalability. Using EMS PCBA strategically can help you increase your manufacturing capabilities and maintain your competitiveness in the ever-changing electronics market, regardless of your goals for launching a new product or optimizing an existing production line.

0