目录

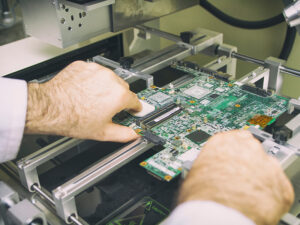

Ball Grid Array (BGA) components are critical in modern electronics, particularly in devices where compact design, performance, and durability are essential. As these components become more prevalent, the need for skilled BGA repair has also increased. This article explores why BGA repair is so important, discussing its technical aspects, benefits, and the role it plays in device longevity and functionality.

The Precision of BGA Repair

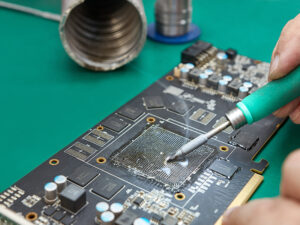

BGA repair is a complex process that demands specialized equipment and expertise. Repairing BGA components typically involves reflowing or reballing the solder balls to restore a stable connection. This process must be done with extreme precision; otherwise, it risks damaging the PCB or surrounding components. Proper BGA repair requires knowledge of soldering techniques, thermal profiles, and careful handling to ensure the repair is successful and reliable.

One common technique in BGA repair is reflow soldering, where the solder balls are heated just enough to melt and create a stable connection. Reballing, on the other hand, involves replacing all the solder balls on the BGA component, providing a more comprehensive solution for components with multiple damaged connections. Both methods require advanced equipment, such as hot-air rework stations, microscopes, and temperature control systems, to achieve the high level of accuracy needed for these repairs.

Benefits of BGA Repair

- Cost Efficiency

One of the primary benefits of BGA repair is cost savings. Replacing an entire PCB or a complex integrated circuit is expensive, especially when dealing with high-end electronics. BGA repair allows for targeted fixes, restoring individual components rather than discarding entire assemblies. For businesses and consumers alike, this approach can significantly reduce repair and replacement costs. - Environmental Impact

Extending the lifespan of electronic devices through BGA repair contributes to sustainability. E-waste is a growing environmental concern, as discarded devices contain hazardous materials and take up space in landfills. By performing BGA repair, manufacturers and repair technicians help reduce electronic waste and the resources needed to produce new components, making it a more environmentally responsible choice. - Device Longevity

Many devices fail due to BGA-related issues, which are often repairable if detected early. By conducting timely BGA repairs, users can extend the life of their electronics, maintaining performance and avoiding the costs associated with purchasing new devices. This benefit is particularly valuable for industries where devices need to function reliably for extended periods, such as medical equipment or military technology. - Improved Performance and Reliability

Faulty BGA components can lead to device instability, affecting performance and reliability. Problems with BGA connections often result in intermittent failures, affecting the device’s function unpredictably. With BGA repair, technicians can restore stable connections, ensuring the device performs as expected without sudden shutdowns or malfunctions. This process is essential for users who rely on their devices for critical tasks, as it enhances the dependability of the equipment.

Objective Considerations in BGA Repair

While BGA repair is beneficial, it is not always the best solution for every device or component. Some BGA issues may be too severe, making replacement the only viable option. Additionally, successful BGA repair requires significant investment in equipment and training, which not all repair facilities possess. For complex or expensive devices, it is worth consulting with a professional to assess whether BGA repair is a cost-effective and reliable option.

Conclusion

BGA repair plays a pivotal role in modern electronics by enabling cost-effective and environmentally friendly solutions for component failures. From ensuring device longevity to improving performance, BGA repair helps users get the most out of their devices. As electronics continue to evolve, the demand for skilled BGA repair services will likely grow, making it an essential part of electronics maintenance and sustainability efforts.

0