目录

Metal surface finishing refers to a broad range of industrial processes designed to alter the surface of metal products. These methods enhance the metal’s appearance, durability, and functionality by applying coatings, removing imperfections, or modifying surface properties. From electroplating to polishing, each technique serves specific purposes, ensuring metals meet performance and aesthetic standards.

Why is Metal Surface Finishing Important?

- Extending Usability: Protects against corrosion, wear, and environmental damage.

- Improving Performance: Enhances electrical conductivity, reduces friction, or strengthens surfaces.

- Aesthetic Appeal: Creates visually attractive finishes (e.g., glossy, matte, or textured surfaces).

- Preparing for Further Processing: Ensures surfaces are clean and smooth for painting or bonding.

Without proper finishing, metals may degrade quickly or fail in demanding applications.

Choosing a Metal surface Finishing Process the right method depends on:

- Cost: Budget for materials, labor, and equipment.

- Surface Quality Requirements: Desired smoothness, reflectivity, or texture.

- Base Material: Compatibility with processes (e.g., aluminum for anodizing, steel for black oxidation).

- Time & Preparation: Some methods require extensive pre-treatment or curing time.

Common Metal Surface Finishing Techniques

1. Plating (Conversion Coatings)

Electroplating:

- Process: Uses an electric current to deposit a thin metal layer (e.g., chrome, nickel, zinc) onto a substrate.

- Benefits: Corrosion resistance, improved conductivity, and decorative appeal.

- Applications: Automotive trim, jewelry, electronic components.

Electroless Plating:

- Process: Chemical deposition of metal (e.g., nickel-phosphorus) without electricity.

- Benefits: Uniform coating on complex shapes; ideal for non-conductive materials.

2. Anodizing

- Process: Electrochemical oxidation of aluminum to create a durable, porous oxide layer (can be dyed).

- Benefits: Excellent corrosion resistance, lightweight, and vibrant color options.

- Applications: Aerospace components, smartphone cases, architectural panels.

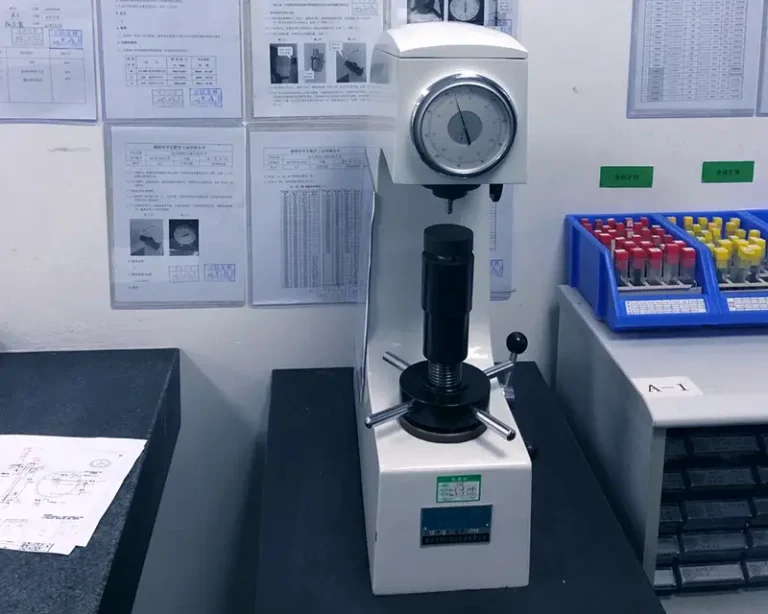

3. Mechanical Finishing

Metal Grinding:

- Process: Uses abrasive wheels to remove material and achieve precise dimensions.

- Applications: Smoothing welds, preparing surfaces for coatings.

Polishing/Buffing:

- Process: Abrasive compounds or wheels create glossy, reflective surfaces.

- Applications: Cutlery, medical tools, decorative hardware.

Brushing:

- Process: Creates uniform linear textures using abrasive belts or brushes.

- Applications: Appliance panels, elevator interiors.

4. Electrochemical & Chemical Methods

Electropolishing:

- Process: Reverse of electroplating; removes surface material to smooth and deburr metal.

- Benefits: Micro-smooth finish, ideal for stainless steel in food and pharmaceutical industries.

Passivation:

- Process: Treats stainless steel with citric or nitric acid to remove contaminants and boost corrosion resistance.

5. Coating Technologies

Painting:

- Types: Solvent-based (durable), water-based (eco-friendly).

- Applications: Automotive bodies, machinery, outdoor structures.

Powder Coating:

- Process: Electrostatic application of dry polymer powder, cured under heat.

- Benefits: Thick, even coatings with no VOC emissions.

Blasting (Sandblasting/Grit Blasting):

- Process: Propels abrasive particles to clean or texture surfaces.

- Applications: Removing rust, and prepping surfaces for painting.

What is the Best Finish for Metal?

- Corrosion Resistance: Anodizing (aluminum), electroplating (zinc/nickel).

- Aesthetics: Mirror polishing, powder coating (color versatility).

- Cost-Efficiency: Phosphating, brushing.

- Durability: Hard chrome plating, laser surface hardening.

Applications of Metal Surface Finishing

- Automotive: Chrome-plated bumpers, powder-coated wheels.

- Electronics: Anodized aluminum laptop bodies, electropolished connectors.

- Construction: Galvanized steel beams, brushed stainless steel railings.

- Medical: Passivated surgical tools, and electropolished implants.

Benefits & Drawbacks of Metal Surface Finishing

Advantages:

- Extends product lifespan by preventing rust and wear.

- Enhances functionality (e.g., reduced friction in engines).

- Offers design flexibility with colors and textures.

- Enables use of cheaper base metals with protective coatings.

Disadvantages:

- Adds production time and cost (equipment, materials).

- Some processes involve toxic chemicals (e.g., hexavalent chromium in plating).

- Thick coatings may alter part dimensions, requiring precision.

Conclusion

Metal surface finishing bridges the gap between raw metal and high-performance end products. Whether it’s the sleek look of anodized aluminum or the rugged durability of powder-coated machinery, choosing the right technique ensures metals meet functional and aesthetic demands. By understanding the strengths and limitations of each process—from electroplating to blasting—manufacturers can optimize quality, cost, and sustainability.

0