目录

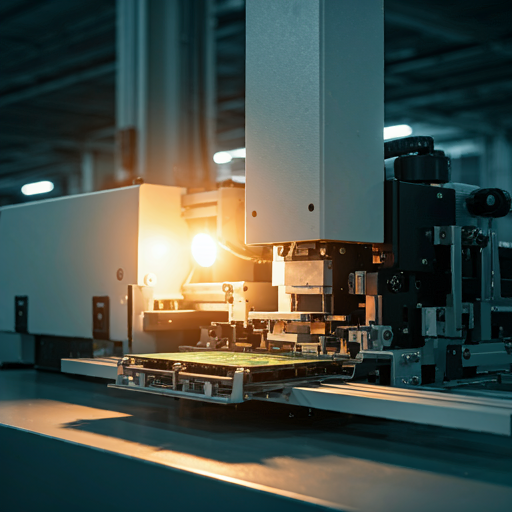

In the world of electronics manufacturing, the PCB Pick and Place Machine is an indispensable tool. Designed to automate the placement of components onto printed circuit boards (PCBs), this machine combines speed, precision, and flexibility. Its advanced features, such as component handling, orientation adjustment, and visual systems, ensure accurate assembly for a wide range of applications.

Component Handling and Orientation

The PCB Pick and Place Machine excels in handling a variety of components, from tiny resistors to larger integrated circuits. Equipped with robotic arms and vacuum nozzles, it picks components from feeders and places them on the PCB with incredible precision.

A key feature of these machines is their ability to manage component orientation. Ensuring that components are correctly aligned is crucial for functionality. The machine’s vision system plays a critical role in detecting and correcting misaligned parts before placement, minimizing errors and enhancing production quality.

Advanced Vision Systems

The visual system of a PCB Pick and Place Machine is one of its most important components. Using high-resolution cameras and image recognition software, the machine identifies the exact position of each PCB and component.

These vision systems are also responsible for quality control. They verify component alignment, solder paste application, and placement accuracy. This reduces the risk of defects and ensures that every PCB meets stringent quality standards.

Accuracy and Precision

Accuracy is at the core of the PCB Pick and Place Machine. Modern machines can place components with micron-level precision, making them suitable for high-density PCBs used in advanced electronics like smartphones and IoT devices.

Precision is further enhanced by servo motors and advanced control systems. These technologies allow the machine to operate at high speeds without sacrificing placement accuracy, which is critical in industries demanding flawless performance.

Flexibility for Various Applications

One of the standout features of the PCB Pick and Place Machine is its flexibility. It can accommodate a wide range of PCB sizes, component types, and production volumes. This makes it ideal for diverse applications across industries such as:

- Consumer Electronics: Smartphones, laptops, and gaming consoles.

- Automotive: Control units, sensors, and advanced driver-assistance systems (ADAS).

- Medical Devices: Pacemakers, diagnostic equipment, and monitoring systems.

- Aerospace: Navigation systems and avionics.

Why PCB Pick and Place Machines Are Essential

The PCB Pick and Place Machine is crucial for modern electronics manufacturing due to its unparalleled efficiency, precision, and versatility. It reduces human error, increases production speed, and ensures consistent quality. Furthermore, as technology advances, these machines continue to evolve, integrating artificial intelligence and machine learning to enhance performance even further.

Conclusion

The PCB Pick and Place Machine is a technological powerhouse that drives innovation in electronics manufacturing. Its capabilities in component handling, orientation correction, and precise placement make it indispensable for producing high-quality, reliable PCBs. As industries push the boundaries of electronics design, these machines will remain at the forefront, ensuring accuracy and flexibility in every assembly process.

0