目录

Choosing the best laser cutter for your business is crucial to achieving optimal results in various projects. Whether you’re an artist working on intricate designs or a manufacturer needing precise cuts, laser cutters are versatile machines that can handle a wide range of materials. This guide will help you understand what to consider when selecting the best laser cutter for your needs.

Selecting the Right Size and Power

The size and power of a laser cutter are the two primary factors that influence its capabilities. The size of the machine determines the surface area it can work on. For example, if you’re working on small projects like etching designs onto a stamp, you’ll need a laser cutter with a smaller laser and a corresponding bed size to fit your material.

Power output is another critical factor. It impacts both the depth and speed of your cuts. For instance, cutting through thick materials like structural foam requires a laser with high power output to ensure clean, precise cuts without damaging the material. Choosing the appropriate size and power for your laser cutter will help you achieve your desired results effectively.

Speed and Precision: Key Factors

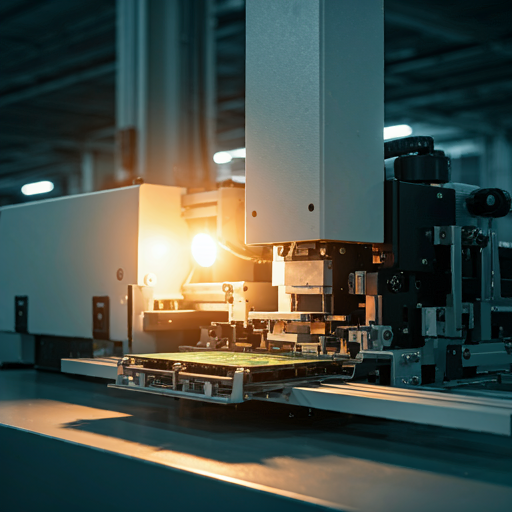

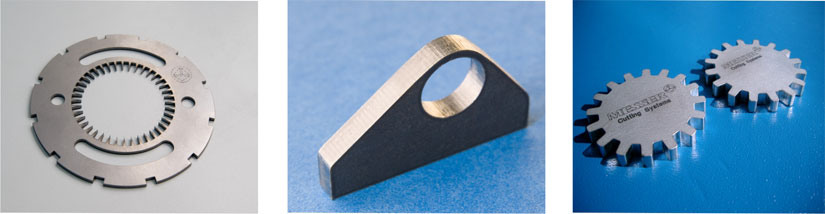

When it comes to laser cutting, speed and precision are essential. A high-quality laser cutter can cut through various materials, such as metal and plastic, leaving clean and accurate edges. This precision is something that traditional cutting tools often cannot achieve.

Laser cutters are widely used for creating detailed, two-dimensional cuts in materials for industrial, manufacturing, and artistic purposes. However, the speed at which a laser cutter operates can vary depending on the material. Some machines are designed to handle multiple materials at different speeds, while others are optimized for specific types of materials. Consider the types of projects you’ll be working on and how much speed and precision you need to choose the best laser cutter for your tasks.

Efficiency and Maintenance Considerations

Efficiency and low maintenance are key characteristics of the best laser cutters. When running a business, it’s important to choose equipment that operates efficiently, reducing both time and costs. An efficient laser cutter will have features such as a large bed size, a powerful laser, and built-in sensors that adjust to the material’s thickness or texture. These features ensure that the machine processes materials quickly and accurately.

Maintenance is another crucial aspect to consider. A laser cutter with low maintenance needs means less downtime for repairs and more time for productivity. Look for machines that come with warranties, as they offer peace of mind and protect your investment. This way, if any issues arise, you can get them fixed without incurring extra costs.

Making the Right Choice

Choosing the best laser cutter involves balancing size, power, speed, efficiency, and maintenance. By carefully considering these factors, you can select a machine that meets your business needs and helps you achieve your goals. Whether you’re working on small artistic projects or large-scale manufacturing, the right laser cutter will enhance your productivity and ensure high-quality results.

0