The sheet metal welding process plays a critical role in determining the final quality and durability of manufactured products. From material handling to weld precision, each step in the process directly influences the structural integrity and long-term performance of the finished product.

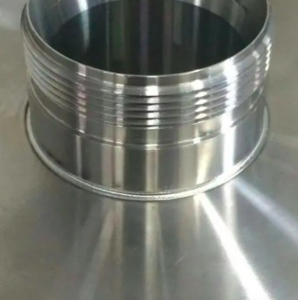

To start, the sheet metal welding process affects the strength of joints. Proper welding techniques create strong connections that can withstand mechanical stress, preventing failures during use. For instance, methods like TIG (Tungsten Inert Gas) welding offer high precision and are ideal for applications requiring clean and reliable welds. This ensures the product performs optimally in demanding environments.

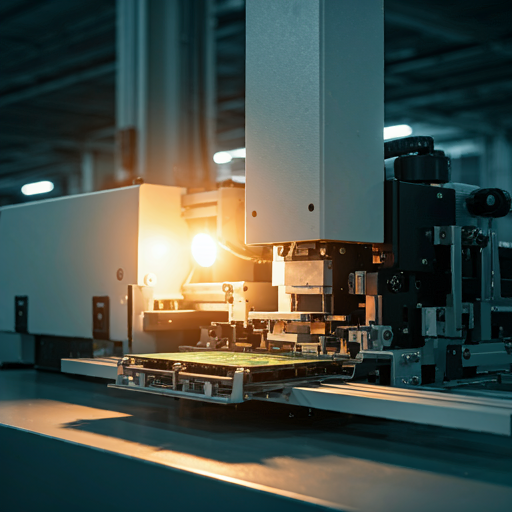

Furthermore, weld consistency is another factor that shapes the product’s quality. In the sheet metal welding process, maintaining uniformity across all welds eliminates weak points that could compromise durability. Automated welding systems equipped with advanced controls are often used to achieve consistent results, enhancing both aesthetic appearance and functional reliability.

Heat management during the sheet metal welding process is equally important. Excessive heat can deform or weaken the base material, leading to reduced durability. Techniques such as laser welding help minimize heat exposure, preserving the integrity of the metal while ensuring strong bonds.

Finally, the choice of filler material significantly influences the final quality. Using compatible fillers in the sheet metal welding process ensures seamless fusion with the base metal, reducing the risk of cracks or corrosion. This attention to material compatibility is essential for extending the product’s lifespan.

In conclusion, the sheet metal welding process has a profound impact on the quality and durability of products. By emphasizing precision, consistency, heat control, and material compatibility, manufacturers can create superior products that meet industry standards and customer expectations.

0