目录

Paper products have become a necessity. They are everywhere you turn and are imperative in our day-to-day lives. There are many different kinds of paper, each with its unique uses. Manufacturing paper products from stone are made from a small percentage of the world’s stone because they can be recycled repeatedly without losing a significant amount of their quality. Manufacturing paper products from stone saves our environment because it does not need trees for pulp production. Also, Stone paper uses very less amount of water than wood paper.

Why Manufacturing Paper Products From Stone?

There are many reasons why we are manufacturing paper products from stone. Here are the top three:

1. By manufacturing paper products from stone, we get stronger and longer paper than any other type of paper product.

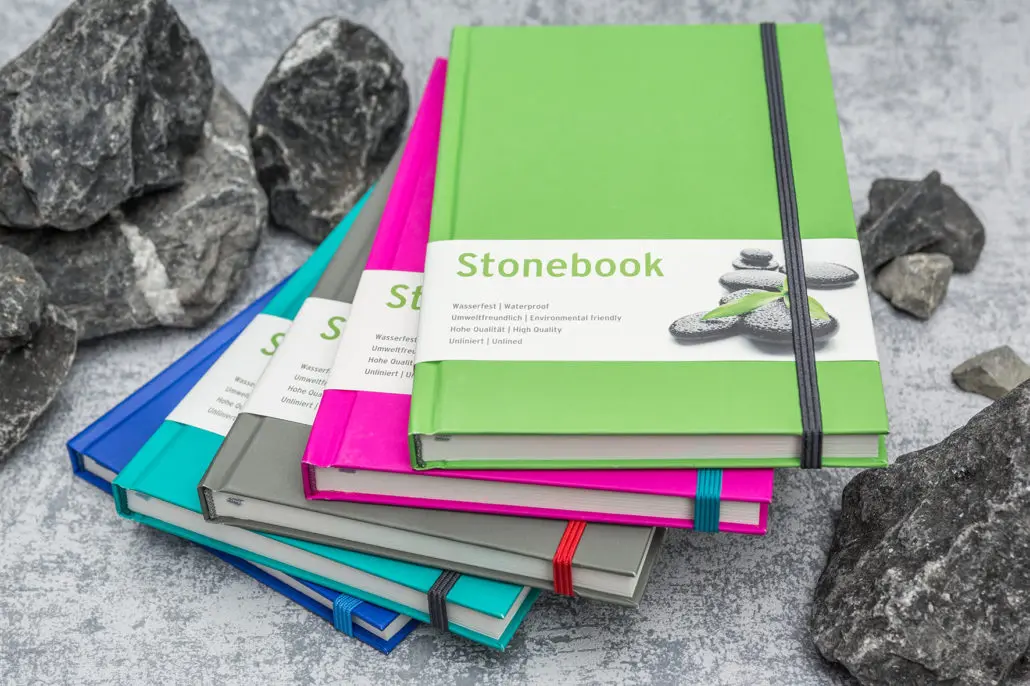

2. Stone paper is more environmentally friendly than wood-based paper.

3. Manufacturing paper products from stone does not cause deforestation, which means there is less impact on the environment.

Stone-based paper is often used for high-end applications such as books, magazines, and newspapers. This is because stone-based paper can last for hundreds of years without deteriorating in any way. This makes it ideal for archiving purposes, but also everyday use such as letters or receipts.

Pulverizing the Stone for Manufacturing Paper Products:

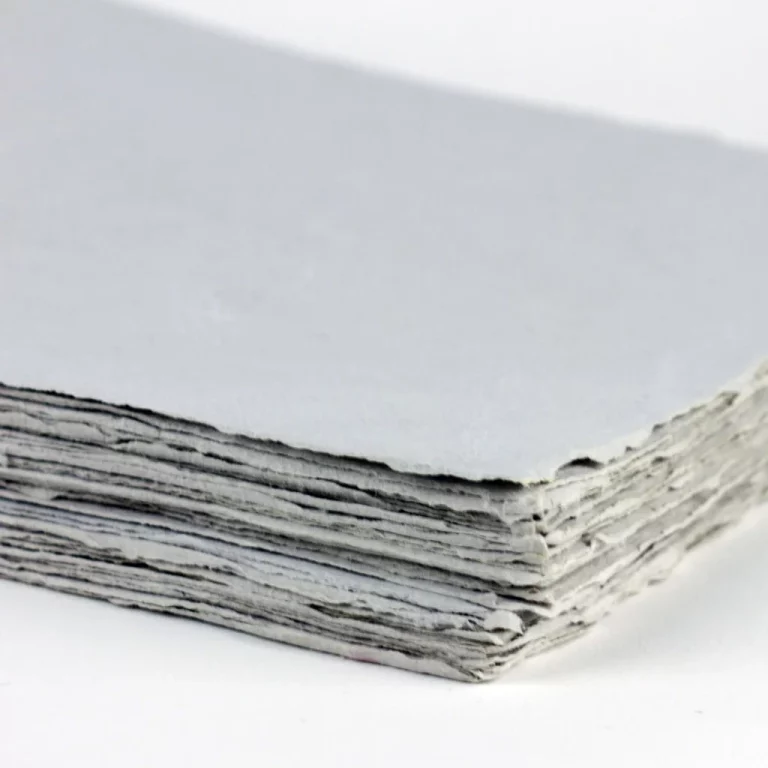

Pulverizing the stone for manufacturing paper products is a very important process. The stone that we use for making paper products is required to be crushed and pulverized to make it suitable for making paper. The primary purpose of pulverizing the stone is to reduce it into small particles so that it can be used in the papermaking process. This process also helps in removing impurities from the stone, which will result in manufacturing paper products of good quality.

The main reason we need to pulverize our stone is that when we use large pieces of stone, it will result in low yield and high wastage during manufacturing. When we pulverize our stones, we will get numerous sizes ranging from 0 to 100 microns, and each size has its specific function in manufacturing paper products. For example, if we want to make fine paper, then we need to use finer pieces of stone as compared with coarse paper where larger pieces are required.

Making Paper Pulp for Manufacturing Paper Products:

One of the most interesting processes in manufacturing paper products is the process of making paper pulp. This process involves several steps and requires a lot of time and effort, but it is worth it because it ensures that you will have high-quality paper products at the end of the day.

Once these rocks have been crushed into smaller pieces, they are mixed with water and then ground down into tiny particles using machines called grinders. These grinders use metal blades or discs to crush the rocks into small particles that can be used to make paper pulp. The next step involves removing any impurities from the crushed rock particles before they go through any further processing steps like drying or cooking processes, which will take place later on down this line during the manufacturing process itself. This palp is then formed into a thin sheet of paper.

The Future of Manufacturing Paper Products from Stone:

The future of manufacturing paper products from stone is bright. The use of stone as a raw material for paper production has been increasing in recent years and will continue to increase in the future. As a result of this trend, there is an increased demand for machinery that can be used to process stone materials. The world has changed in recent years. We’ve seen an increase in population, an increase in education levels, and an increase in access to technology. As a result of these changes, we’ve also seen an increase in awareness about our environment. This is why many people are looking for ways to reduce their carbon footprints or recycle more materials than ever before. The main advantage of using stone as a raw material for manufacturing paper products is its high strength, which allows the finished product to be strong and durable. Another advantage is that it has a low density, which makes it easy to transport and store.

Conclusion

The shift towards manufacturing paper products from stone represents a significant step towards sustainability and environmental conservation. By utilizing stone as a raw material, we can create durable, long-lasting paper products without the need for deforestation. This innovative approach not only offers a more environmentally friendly alternative to traditional wood-based paper but also addresses the growing demand for sustainable materials in a world increasingly focused on reducing carbon footprints and promoting eco-friendly practices. As the use of stone-based paper continues to gain traction, it is clear that the future of manufacturing paper products from stone is promising, offering a viable and impactful solution for a more sustainable paper industry.

0