目录

Electrical cables are used for the transmission of electricity. While they are a convenient means for electricity transmission, proper safety measures are equally important for multiple reasons such as leakage or loss of electricity, short circuits (which may lead to fire), and electrical shock. This is where electrical cable insulation comes in, and why it deserves so much attention.

Types of Electrical Cable Insulation

While any non-conductor of electricity could act as insulation, selective materials are used for electrical cable insulation keeping the longevity, nature of transmission, and surrounding environmental conditions in mind. Typically, these three types of insulation are used.

Plastic Electrical Cable Insulation

Plastic insulation is the most commonly used electrical cable insulation. The greatest advantage of this is cost-effectiveness, therefore it is commonly used for normal usage at homes and offices. Even within plastic insulation, different types of materials are employed for different purposes.

Common applications for plastic insulation include the medical, and food industries, interior home design, and low-temperature environments.

Rubber Electrical Cable Insulation

Rubber electrical cable insulation offers better flexibility in low-temperature environments, and has remarkable resistance to abrasions and corrosion. Therefore, rubber insulation is the preferred choice for electrical cables that require extremely high or low temperatures and high-voltage transmission. Different types of both natural, as well as synthetic rubber, are used for this purpose.

Common applications for rubber insulation include heat treatment plants and kilns, lead wire, coils, and transformers.

Fluoropolymer Electrical Cable Insulation

Fluoropolymers are known to be extremely resistant to certain corrosive elements particularly acids, bases, and other corrosive agents and solvents. Therefore, fluoropolymer electrical cable insulation is usually used in conditions where the wire is more prone to corrosive chemicals, or high UV exposure.

Common applications for fluoropolymer insulation include military applications, the automotive and car industry, and common household appliances.

Uses of Electrical Cable Insulation

There are various reasons why appropriate electrical cable insulation is necessary. Some of these reasons are:

- Safety is paramount especially when it comes to electrical appliances and transmission cables. Damaged or poor insulation increases the risk of power loss, short circuits, and equipment failure. There is also a higher risk of electrical shock in poorly insulated electrical cables, which could be fatal in some cases. Moreover, the risk is even greater during wet climates and rainfall seasons.

- Proper electrical cable insulation enhances the life of electrical cables. A metallic wire without insulation not only gets prone to corrosion but also loses transmission capacity based on. Moreover, it also offers protection against wear and tear caused by rubs and friction.

- Transmission losses could result in serious financial losses depending upon the transmission capacity. Proper insulation protects against any such power loss and proves to be economically beneficial as well.

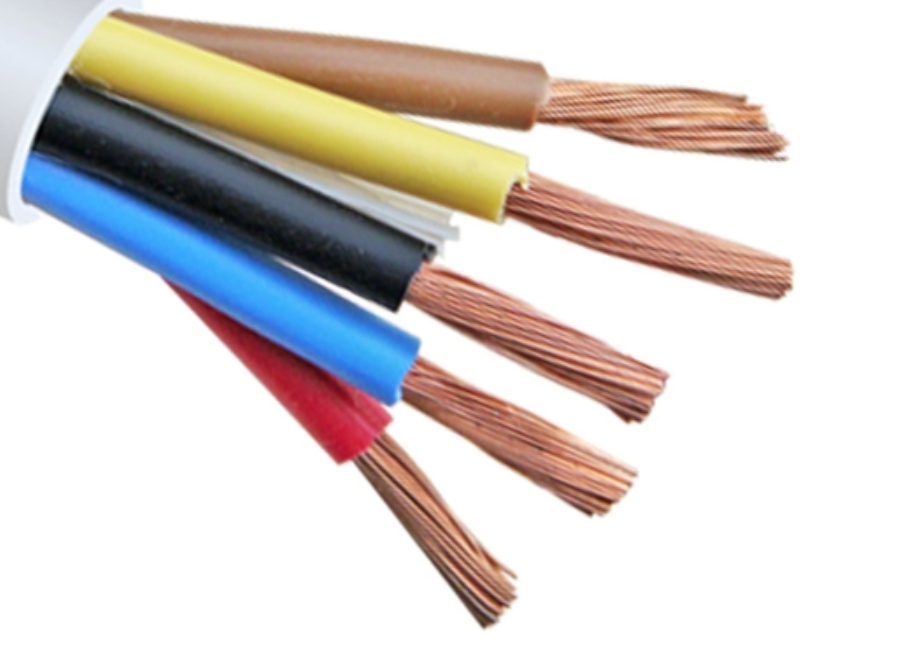

- Insulation also helps color code the wire according to certain standards. Moreover, it also helps differentiate between the hot wire and earth wire, which is highly convenient.