目录

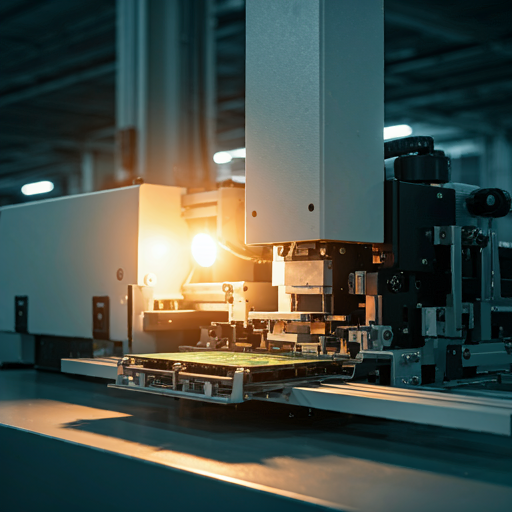

What is Co2 Laser Marking Machine?

Co2 laser marking machine is one kind of gas laser marking machine which is based on a carbon dioxide gas mixture. Co2 laser marking machine is mainly used for working with non-metallic materials. It has very good beam quality and most widely used laser type. It is marked with low intensity as compared to Fiber laser marking machines. It uses CO2 gas in a sealed tube as a laser source to mark different organic materials. The co2 laser marking machine is ideal for high-speed precision marking. It is extensively used in food, electronic components, drug, and alcohol packaging, integrated circuits, mobile communications, building materials, and PVC pipes. This laser system is widely renowned and accepted for product identification, traceability, date sampling, etc. Co2 laser marking machine mostly applications are given below:

- It’s used for most plastic materials like PP, ABS, PVC, PBT, etc.

- Wood

- Foils and films

- Acrylic

- Pet bottles

How CO2 Laser Marking Machine Systems Work?

A CO2 laser marking machine is a molecular gas laser based on a gas mixture containing carbon dioxide, helium, nitrogen, hydrogen, water vapor, and xenon. The laser comes from a gas discharge due to AC or DC electricity. The nitrogen molecules are excited when they are released into a metastable state of vibration. As a result, they transfer the energy to CO2 molecules when they collide with them. The laser beam from the laser tube evaporates the surface of the target material, and then exposes a deeper layer to create the mark you want. Helium facilitates heat removal and returns the co2 molecules to their ground state. At last, the hydrogen and water vapor help to reoxidize carbon monoxide.

Features of Co2 Laser Marking Machine

- Co2 laser marking machine is a commonly used laser marking method that has the advantages of high quality and good beam quality.

- It is mainly used in non-metallic industries such as craft gifts, wood, clothing, greeting cards, fabric so on.

- The carbon dioxide is a gas laser that electronically stimulates the carbon dioxide gas mixture to leave permanent marks on the surface.

- And this technology can engrave wonderful patterns, logos, dates, and text on the surface of the product.

Benefits of Using Co2 Laser Marking Machine

Important benefits are that manufacturers can gain many benefits from the laser marking process, whether it is basic part identification and branding or complete traceability to track and trace parts from cradle to grave. Direct part marking with a CO2 laser marking machine delivers durable, readable marks. Here are the results of high-quality marks include:

- Firstly, its greater operational efficiency and productivity with less waste and downtime saves your wealth.

- You can get more visibility and accountability throughout the supply chain.

- Minimize the problem of high prices, and quality counterfeiting.

- Ensured compliance with industry regulations and can be benefited.

When buying a CO2 laser marking machine, it’s essential to take into account factors like power options, material compatibility, customization features, and maintenance needs. By carefully evaluating these aspects, you can find a machine that meets your marking requirements and improves the efficiency of your operations.

0