目录

The stone paper industry is particularly prominent in environmental protection. Unlike the traditional papermaking process, stone paper production does not produce waste gas, water, and waste residue. It is a non-polluting green environmental protection project.

In terms of water use, each ton of traditional paper production consumes 100 tons of freshwater. In contrast, the entire stone paper industry production does not require water.

The primary raw material used in traditional papermaking is forest resources. Furthermore, the primary raw materials of stone paper production are coal gangue, slag, and other stone materials, which do not consume forest resources.

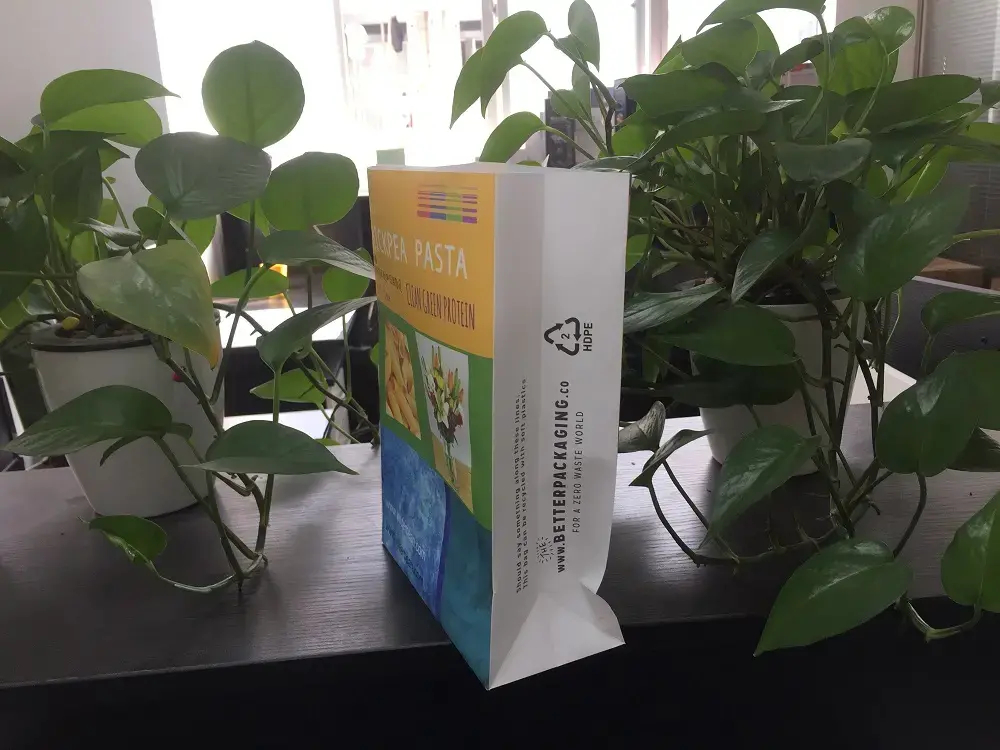

Handling of stone paper products

Traditional fiber paper can be recycled into recycled paper after being used up to achieve resource reuse. Thermoformed stone paper can also be recycled and reused. After recycling, it can produce darker-colored wrapping paper. It can also be made into various signs and flower pots for the stone paper market.

The used stone paper is recycled or treated like garbage. When it is burned in an incinerator, the only non-toxic resin can be burned. Stone powder can promote contact between the resin and the air, accelerate complete combustion, and not produce black smoke due to the lack of oxygen and smoldering. There is no toxic exhaust gas after combustion with minimal carbon dioxide emission, which helps to slow down and improve the situation of global warming resulting from carbon dioxide.

Even when discarded outdoors, the stone paper will automatically embrittle into broken eggshells after being exposed to sunlight for about six months. It thus restores the earth and returns to nature. When buried in the ground for a year, it degrades, becoming a powder. Therefore, it will not cause environmental pollution.

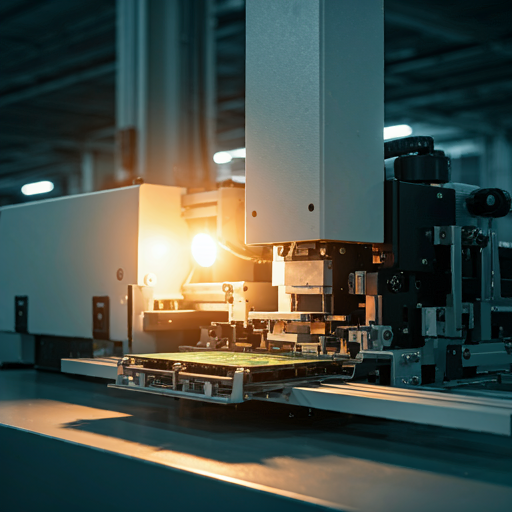

Production of stone paper products

For ordinary paper, a large amount of water may be used in the production process. However, the thermoforming stone paper uses almost no water, and the process is never bleached. Therefore, the biggest difference between the stone paper industry and ordinary paper is that the primary color of stone powder will affect the color of the paper. For example, coal gangue paper will be slightly black, depending on the paper’s purpose and the stone paper market.

0